Professional Cane Sugar Processing Chemicals: Superior Outcomes

Professional Cane Sugar Processing Chemicals: Superior Outcomes

Blog Article

Unleash the Possible of Your Operations With Proven Cane Sugar Processing Chemical Formulations

In the world of walking cane sugar handling, the mission for functional excellence is a consistent search. The utilization of tested chemical formulas has emerged as a critical component in enhancing manufacturing processes and raising general performance.

Enhancing Production Effectiveness

To optimize manufacturing efficiency in walking cane sugar handling, it is important to enhance operational processes and adopt innovative technologies where applicable. By applying effective operational treatments, such as automating hand-operated tasks and using data-driven insights, sugar handling plants can dramatically boost their efficiency levels.

Furthermore, integrating state-of-the-art modern technologies like man-made knowledge and maker knowing can even more change the cane sugar handling market. These modern technologies can evaluate substantial quantities of data to optimize procedure specifications, forecast equipment maintenance requires, and boost general plant performance. By accepting automation and digitalization, sugar handling facilities can run with greater accuracy and reliability, ultimately bring about raised manufacturing outcome and improved product quality. Essentially, the pursuit of production effectiveness via structured processes and innovative modern technologies is vital for the sustainable development and competitiveness of cane sugar handling operations.

Maximizing Yields and Pureness

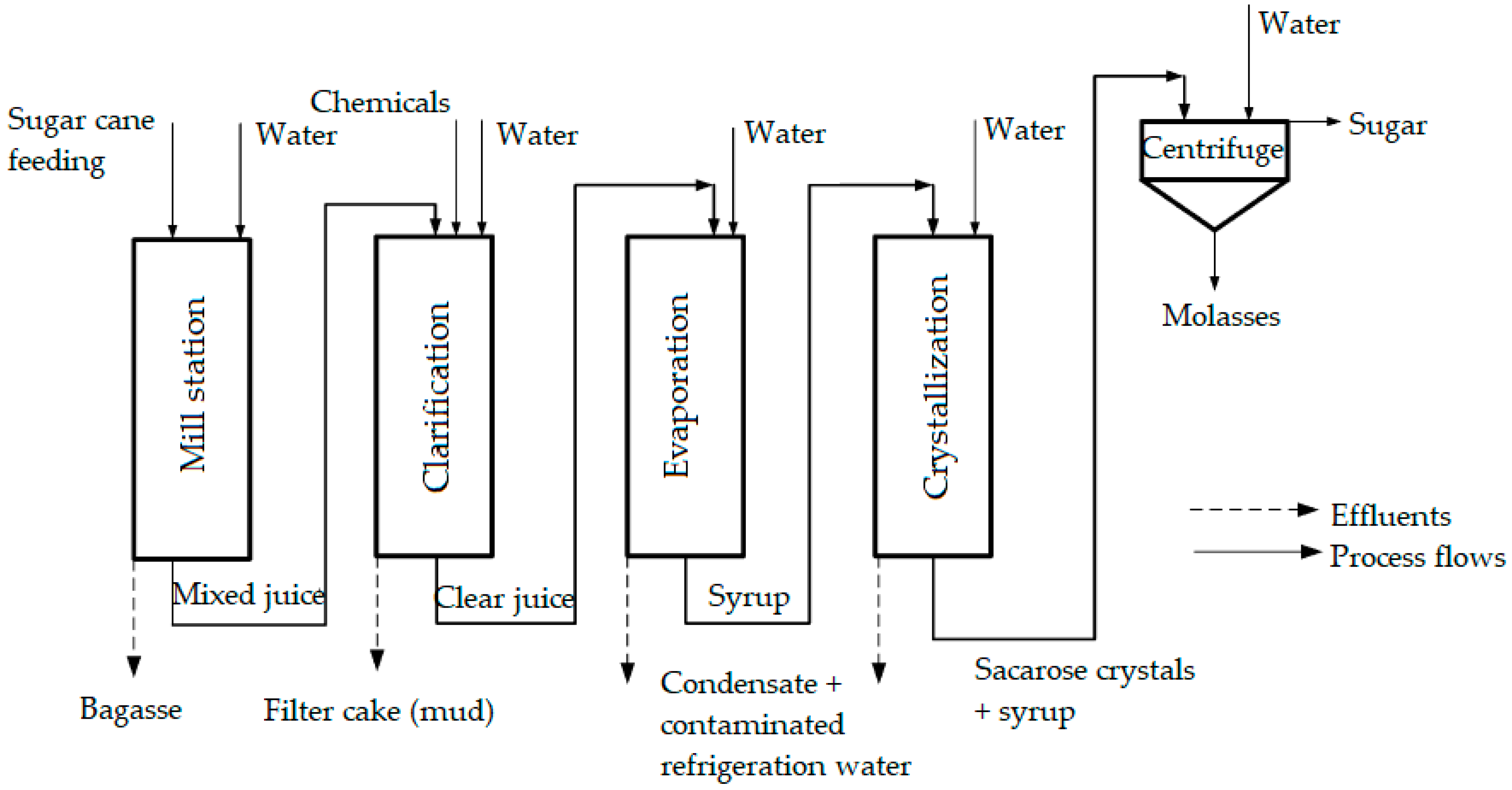

Successfully taking full advantage of yields and preserving high pureness degrees are crucial goals in the walking cane sugar handling sector. Achieving optimum yields while upholding rigorous pureness criteria needs a critical method that integrates sophisticated chemical formulas into the handling process. By employing specialized chemicals created to improve removal efficiency, clarify the juice, and enhance crystallization processes, sugar mills can dramatically improve their overall returns and purity degrees.

Improving Refine Optimization

In the world of walking stick sugar processing, enhancing process optimization is vital for attaining the wanted yields and pureness degrees while integrating advanced chemical formulas for boosted efficiency. Routine upkeep timetables and thorough cleansing treatments also play an essential function in maintaining the handling plant running smoothly and preventing unanticipated downtime. Welcoming procedure optimization as a core principle can lead to sustainable enhancements in performance and product quality within the walking cane sugar handling sector.

Getting Operational Goals Effectively

With a strategic concentrate on operational excellence, the sugar processing industry intends to successfully fulfill its production targets and high quality requirements. Accomplishing operational goals effectively requires a mix of variables such as streamlined processes, advanced technologies, and maximized chemical solutions. By making sure that each action of the sugar processing operation is thoroughly prepared and carried out, business can enhance effectiveness and efficiency.

One key aspect of attaining functional objectives is the option of high-grade walking stick sugar processing chemical formulations. These solutions play a vital duty in numerous phases of the manufacturing procedure, including removal, filtration, and formation. By utilizing proven chemical formulas especially made for cane sugar handling, business can improve return, reduce processing time, and enhance the total top quality of the last product.

Furthermore, reliable interaction and partnership amongst various divisions within the company are essential for aligning functional goals and making sure smooth process - Cane Sugar Processing Chemicals. Regular efficiency evaluations, constant training programs, and data-driven decision-making processes can additionally sustain the accomplishment of functional quality in the sugar handling industry. By applying these methods, companies can let loose the complete potential of their operations and stay in advance in a competitive market

Enhancing Output Top Quality

Additionally, improving output high quality additionally needs continual surveillance why not try this out and modification of processing criteria to keep uniformity and fulfill quality specifications. Quality control procedures such as routine testing for pureness, dampness material, and granulation guarantee that the end item fulfills market requirements and client expectations. By purchasing the best chemical solutions and focusing on quality throughout the production procedure, sugar handling facilities can achieve premium output quality that sets them apart in the market.

Conclusion

To conclude, description utilizing proven walking stick sugar processing chemical solutions can substantially enhance production performance, find more take full advantage of yields and pureness, improve procedure optimization, attain functional objectives successfully, and boost output top quality (Cane Sugar Processing Chemicals). By incorporating these formulations right into procedures, business can open the complete possibility of their sugar handling facilities and ensure a more streamlined and effective production procedure

Report this page